Laboratories that specialise in transformer oil analysis offer a good standard service but are limited in the diagnosis provided.

Relying on software that produces a diagnosis may be acceptable in most cases where there is little activity or where nothing unusual is noted.

But when anomalies are noted, or critical action is advised this is where we can assist.

With ADAM we provide detailed diagnosis on problems noted by analysis from any laboratory, giving guidance to engineers and operators on actions required and likely time frames for remedial actions.

Our specialist knowledge in renewables or in the case of aged transformer fleets, our in-depth diagnoses and advisories can save money, prevent failures and extend asset life.

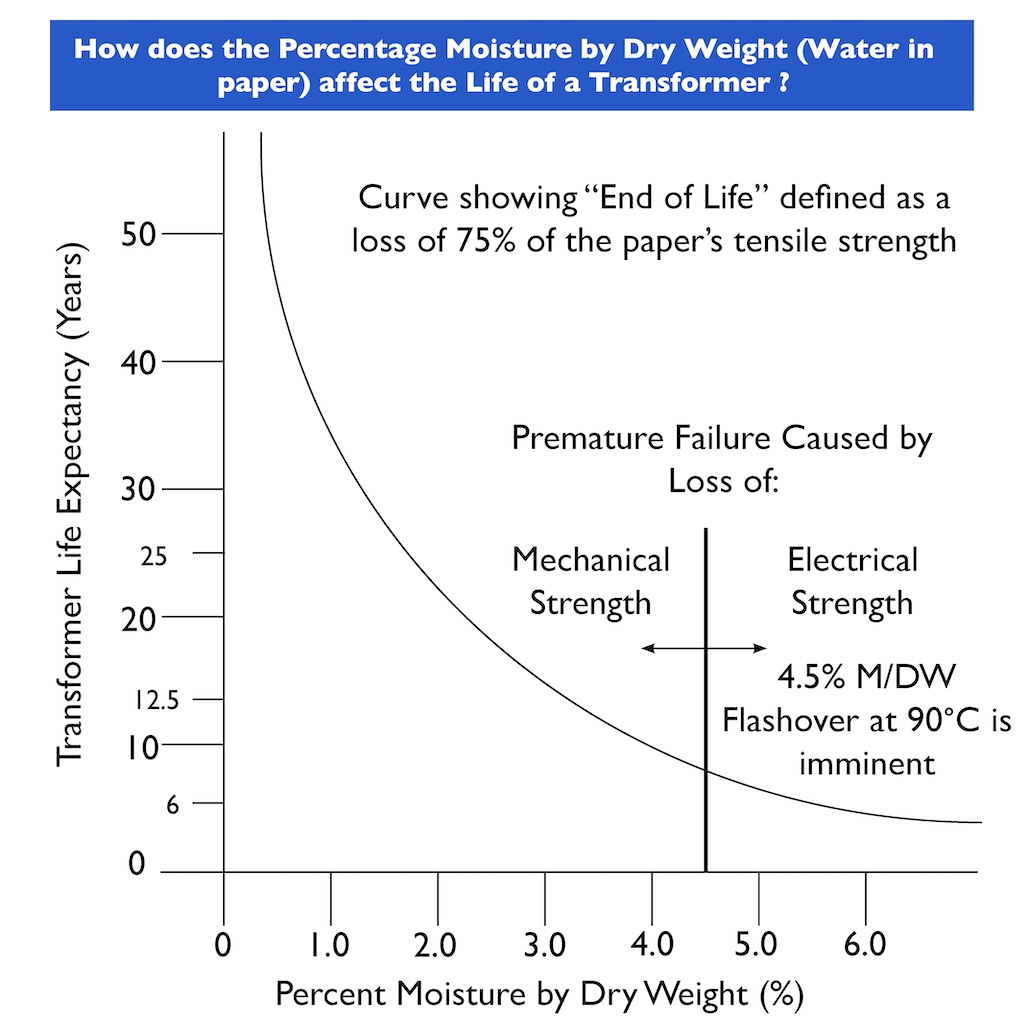

A new transformer is a significant investment. The potential life of a new transformer is largely dependent upon the life of the paper insulation as this cannot be repaired in situ. Once paper life deteriorates it is gone forever and cannot be restored.

It follows that any action we can take to maintain the paper in a healthy, dry and contaminant free condition will optimise and extend the asset life as well as reduce the risk of failure.

With Sentinel (ICU)® installed, the life of new transformer assets is optimised, potentially doubling expected life, maintaining the oil and the paper insulation free from moisture, acids, and sludge buildup. The graph here shows how the buildup of moisture in the paper insulation can dramatically shorten transformer life and increase the risk of failure.

Our advanced diagnostics provide operators and maintenance personnel with timely guidance on remedial actions required to reduce or remove the risk of failure.

This allows maintenance operations to schedule more effectively saving time and optimising planning.

It has been estimated that more than 60% of transformers worldwide are 35 years or older. Managing these ageing asset bases is a complex and time-consuming task and often comes down to timed replacement rather than managed life.

With Sentinel (ICU)® installed on an in-service, aged transformers it replaces conventional periodic drying or regeneration operations by continuously sweeping the oil and paper insulation, removing excess moisture, acids, dissolved as well as deposited sludges.

Periodic drying or repeated regeneration is no longer required.